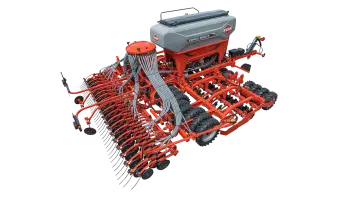

Offset tamping wheels for fuel savings

The tamping wheels of the ESPRO RC range seed drills are staggered in 2 rows offset by 200 mm to avoid the “bulldozer” effect. Dirt and residue do not accumulate at the front of the wheel assembly. Their large diameter (900 mm) limits rolling resistance and thus limits the required pull power. Their narrow profile facilitates the flow of soil and residue. Note that these wheels are not linked together, which avoids marking at the end of the field. Finally, the “square” tread pattern of the tyres ensures uniform tamping of the seeding lines. A unique concept combining seeding precision, power and fuel savings and high work output!