Genuine parts for KUHN hay & silage-making equipment

Forage can be of lower quality if the spare parts on your hay & silage-making machines are not adapted. Choosing your agricultural parts is an important part of a successful harvest....

Forage can be of lower quality if the spare parts on your hay & silage-making machines are not adapted. Choosing your agricultural parts is an important part of a successful harvest....

To plough effectively, it is important to choose the right parts for your machine. KUHN’s plough parts are designed to fit your KUHN plough perfectly. Given that these genuine spare parts were created...

When it comes to maintaining optimum performance and extending the life of your baling and wrapping machines, nothing beats the use of genuine parts. With an unwavering commitment to innovation and re...

When you own a KUHN spreader, it is crucial to consider the importance of wearing parts such as flails and hammers. These parts play an essential role in the smooth running of your machine and the qua...

Discover our complete range of agricultural spare parts specially designed for KUHN livestock farming equipment. As specialists, we can provide you with all the products you need to keep your machiner...

For healthy crop growth, product application must be precise, so it is essential that the different sprayer parts are in good condition. You can’t afford to stop your spraying job in the middle of the...

We are proud to offer you a complete selection of tillage wear parts specially designed for your KUHN agricultural equipment. Many wear parts are available for your powered or non-powered tillage equi...

Welcome to our page dedicated to all original KUHN seed drill parts. The range of seed drill parts includes everything you need to ensure accurate fertilisation and even seed distribution. Whether you...

As a farmer, you know how essential regular maintenance of your agricultural equipment is to ensure optimum performance and prolong its life. When it comes to your KUHN shredder, choosing genuine KUHN...

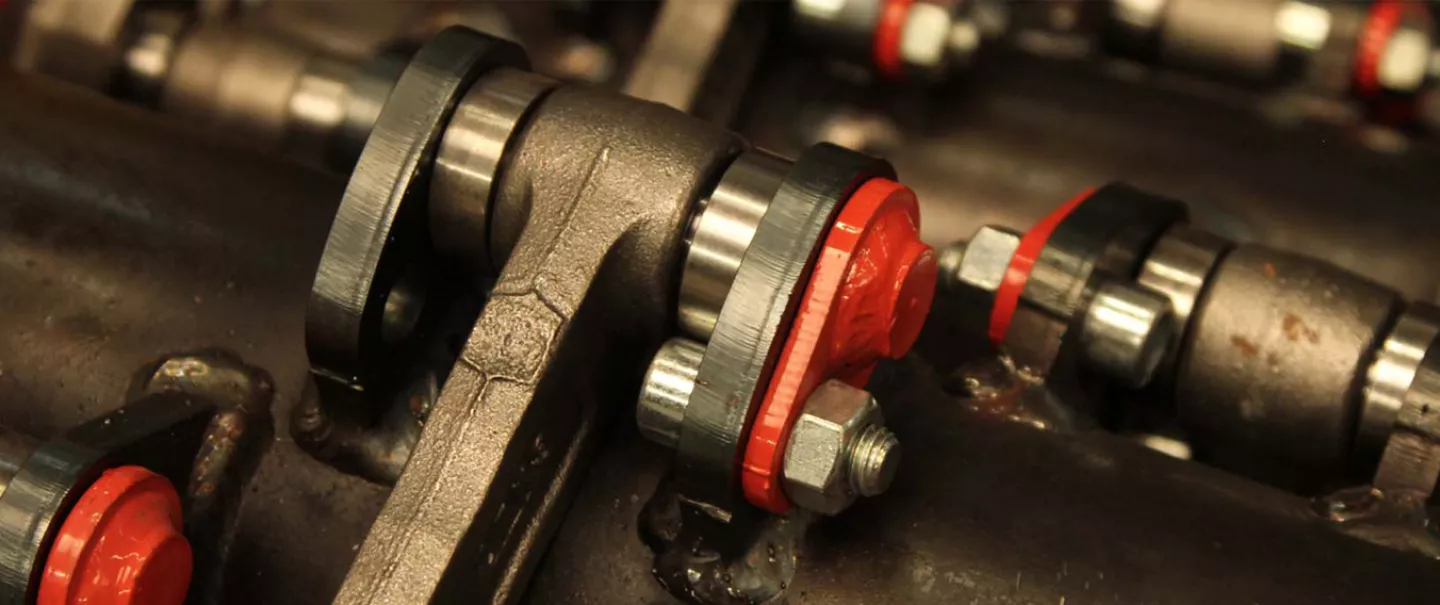

Ground speed is an important parameter which strongly affects the service life of wearing parts. Double the speed and you multiply wear by four.

Speed and the tillage method affect the service life of your wearing parts. Correct machine setting also optimises working depth, limits consumption and reduces traction-power requirements

Working in dry conditions increases wear considerably. In addition, working in frozen ground has an impact on wear, whereas working on a wet plot can reduce the issue.

From one plot to the next, the texture of the soil varies significantly. Wear depends greatly on the type of soil. In flinty and sandy soil, for example, parts will wear out faster.

KUHN agricultural parts are designed to fit the machines that they were made for, perfectly. They are produced specifically for the machine, to provide optimal output quality, keep power requirements down, and ensure that the machine, as a whole, works smoothly.

When you hitch a KUHN agricultural machine to a tractor, you benefit from a wide range of KUHN parts adapted to your needs:

Find out more about carbide parts

Read moreWith a full range at your disposal, you are sure to make the right choice and maximise your performance. KUHN machines and parts are the winning combination in every field!

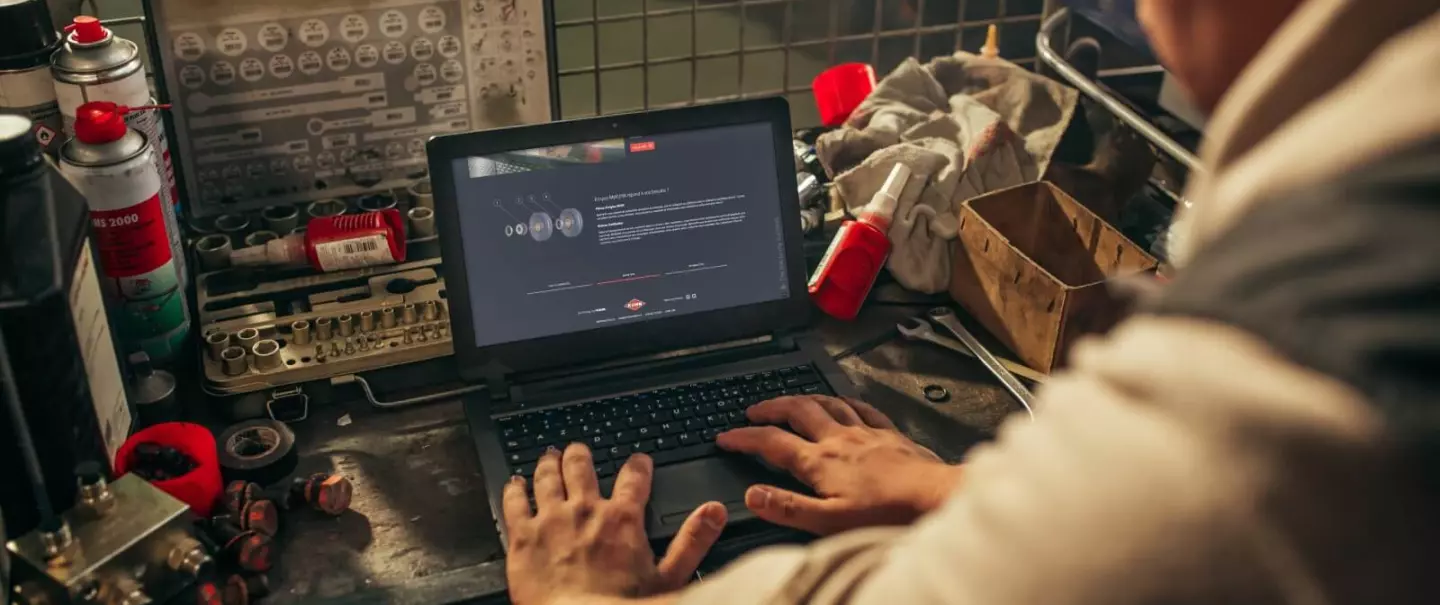

To increase your productivity, find all the parts you need on MyKUHN. View the catalogue for free.

Find all the parts and the catalogue directly on MyKUHN.

Subscribe quickly and for free!

Go to MyKUHNIn keeping with this old saying, forging and heat treatment have been the core activity of our French factory in Châteaubriant (Loire-Atlantique) since the beginning of the 20th century. With this world-renowned know-how we can offer cutting-edge machines and parts that rival time.

KUHN has the capacity to produce its own parts, such as wearing parts for the plough and, therefore, master the entire production chain. These are firm commitments that ensure you get the productivity and quality that you expect from our parts every day of the year.

Cast iron parts, such as our rake housings, are designed, developed, and produced in our historical French factory in the heart of Alsace. Our unique know-how gives us mastery over our production processes as well as the certainty that the parts on your machines are top quality.

From moulding to quality control, all steps are carried out with precision, to provide you with the highest level of reliability and guarantee that has given our machines the good name they have today.

Find the closest dealer to your farm.