Reduced weight combined with compactness on a large model

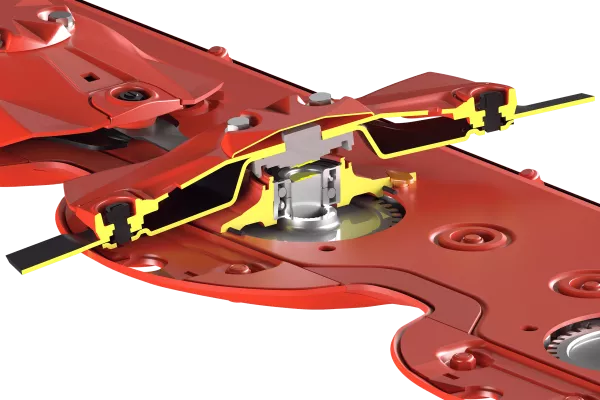

Limiting weight and stress on tractor components are key criteria in machine design. As such, a brand-new frame concept and support arms for the mower-grouper units make the machines lighter and more compact, and the centre of gravity is 15 cm further forward compared to conventional machines. The conveyor belt frames are made of aluminium, further reducing machine weight. A lighter weight is also an advantage at work: lower power requirement and less soil compaction. In addition, the hydro-pneumatic suspension system improves ground following.