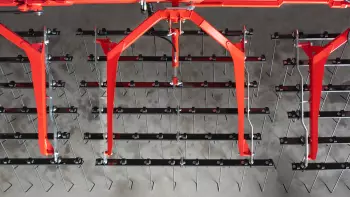

Specially designed tines

Each section of the TINELINER tine weeder is 1.50 m in width. It is equipped with 48 tines, 540-mm long by 7 mm in diameter, positioned in 6 rows, to improve soil and weed flow-through.

The length-to-diameter proportions are the result of rigorous studies, producing the optimum balance between flexibility and rigidity, for maximum weeding effectiveness.

The length-to-diameter proportions are the result of rigorous studies, producing the optimum balance between flexibility and rigidity, for maximum weeding effectiveness.