4 electric proportional functions as standard!

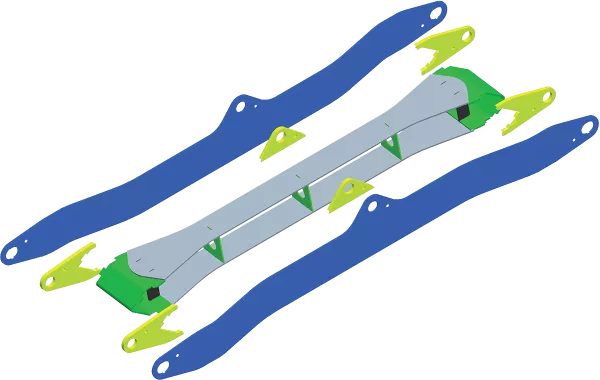

The PRO-LONGER GII hedge and grass cutters are controlled with 4 electric proportional functions: pivot, main boom, outer boom and flail head orientation. The movement speed increases exponentially as the joystick is shifted further along one direction. The machine allows for smooth and precise operation, while providing unbeatable driving comfort.

For increased safety and precision, the proportional effect works in both directions: up and down. Precision is guaranteed regardless of the type of job (verge, bank, ditch, hedge, etc.).

For efficiency, the functions of the main boom, outer boom, flail head orientation, pivot and floating head can be activated simultaneously with the ergonomic joystick and the position of the various buttons. The EP joystick can also be adjusted to the size of your hand.

The EP joystick is easy to install even in the smallest cabs. It is connected to the machine by a single small-diameter electric cable.

For increased safety and precision, the proportional effect works in both directions: up and down. Precision is guaranteed regardless of the type of job (verge, bank, ditch, hedge, etc.).

For efficiency, the functions of the main boom, outer boom, flail head orientation, pivot and floating head can be activated simultaneously with the ergonomic joystick and the position of the various buttons. The EP joystick can also be adjusted to the size of your hand.

The EP joystick is easy to install even in the smallest cabs. It is connected to the machine by a single small-diameter electric cable.