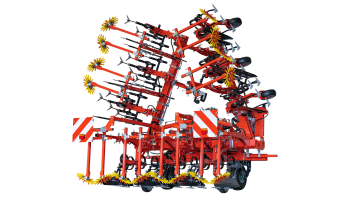

Parallelogram: a key feature

The parallelogram concept is one of the keys to the high-performance capacity of the mechanical weeder. The longer the parallelogram, the better the ground contouring on uneven ground. In addition, enables soil penetration of up to 120 kg per weeding unit, even at high speeds and on plots with slake crusts.